Personal Food Computer v3.0

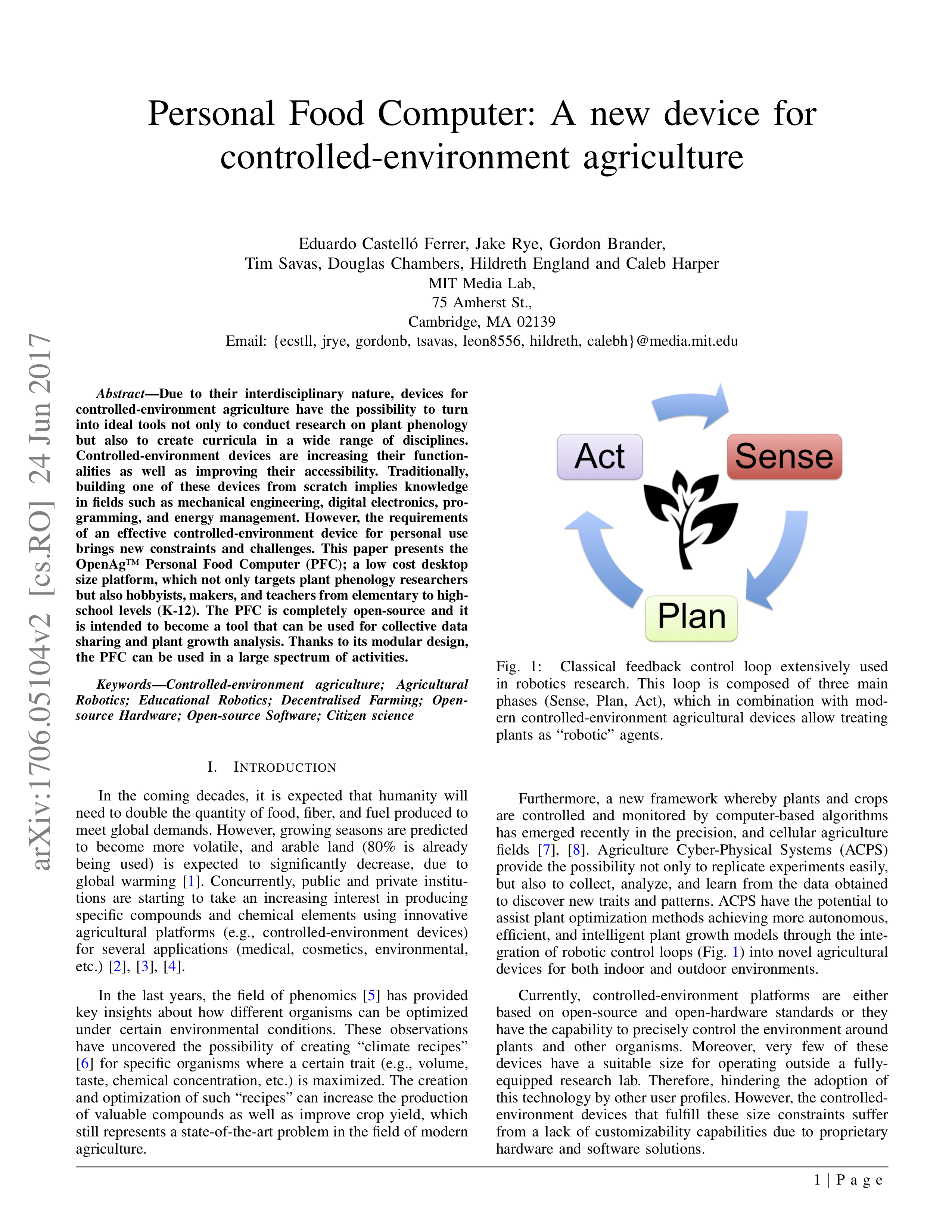

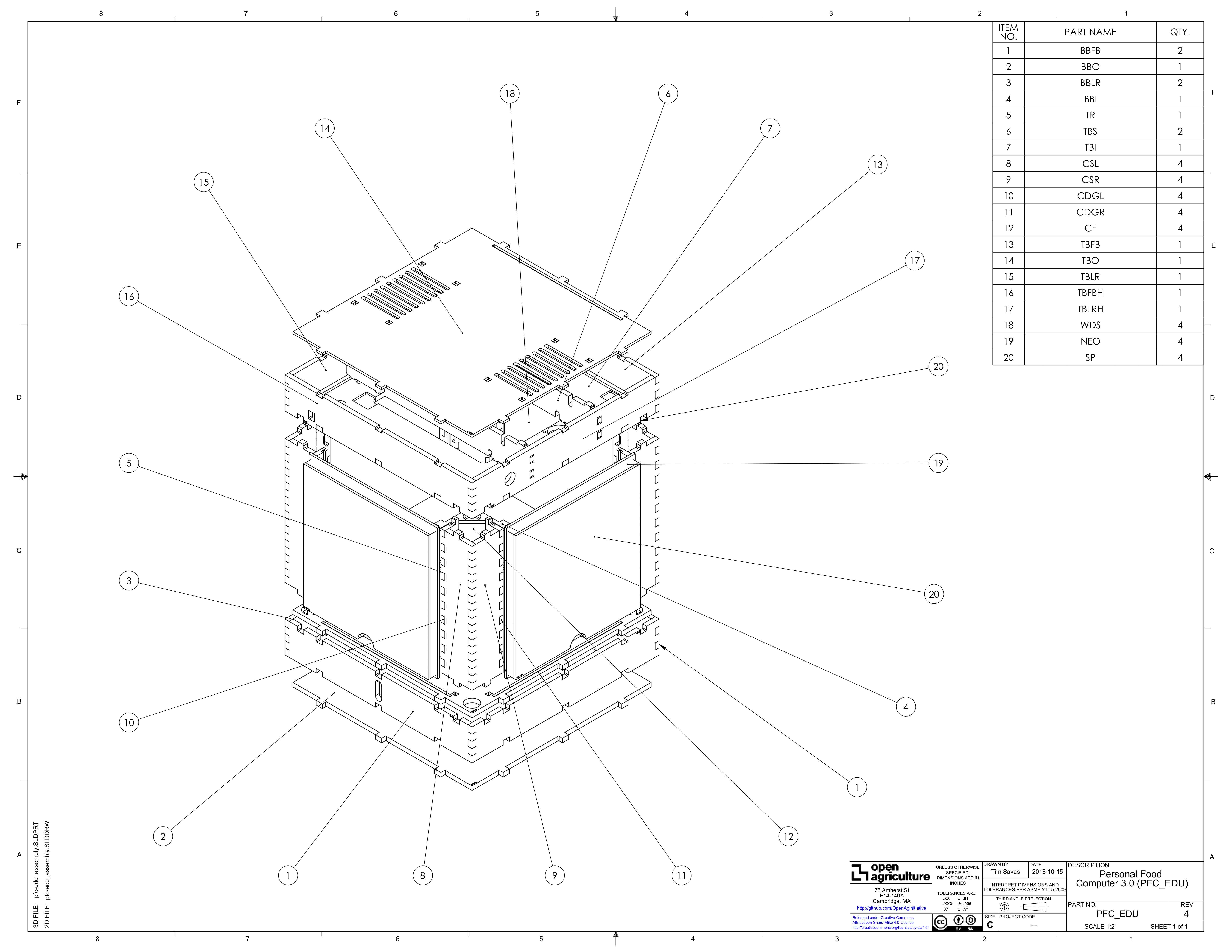

The Personal Food Computer v3.0 is the MIT Media Lab Open Agriculture Initiative’s latest desktop controlled environment growth chamber. We made the Personal Food Computer simpler and smarter than it's ever been. The unit doesn’t require tools for assembly, can be flat packed for easy transport, and sends data to a cloud database. Other new features are abound. I led chassis prototyping and manufacturing for our release in 2018. Described here are my contributions. Check out my team's Wiki and Github pages for a fuller picture.

Iteration

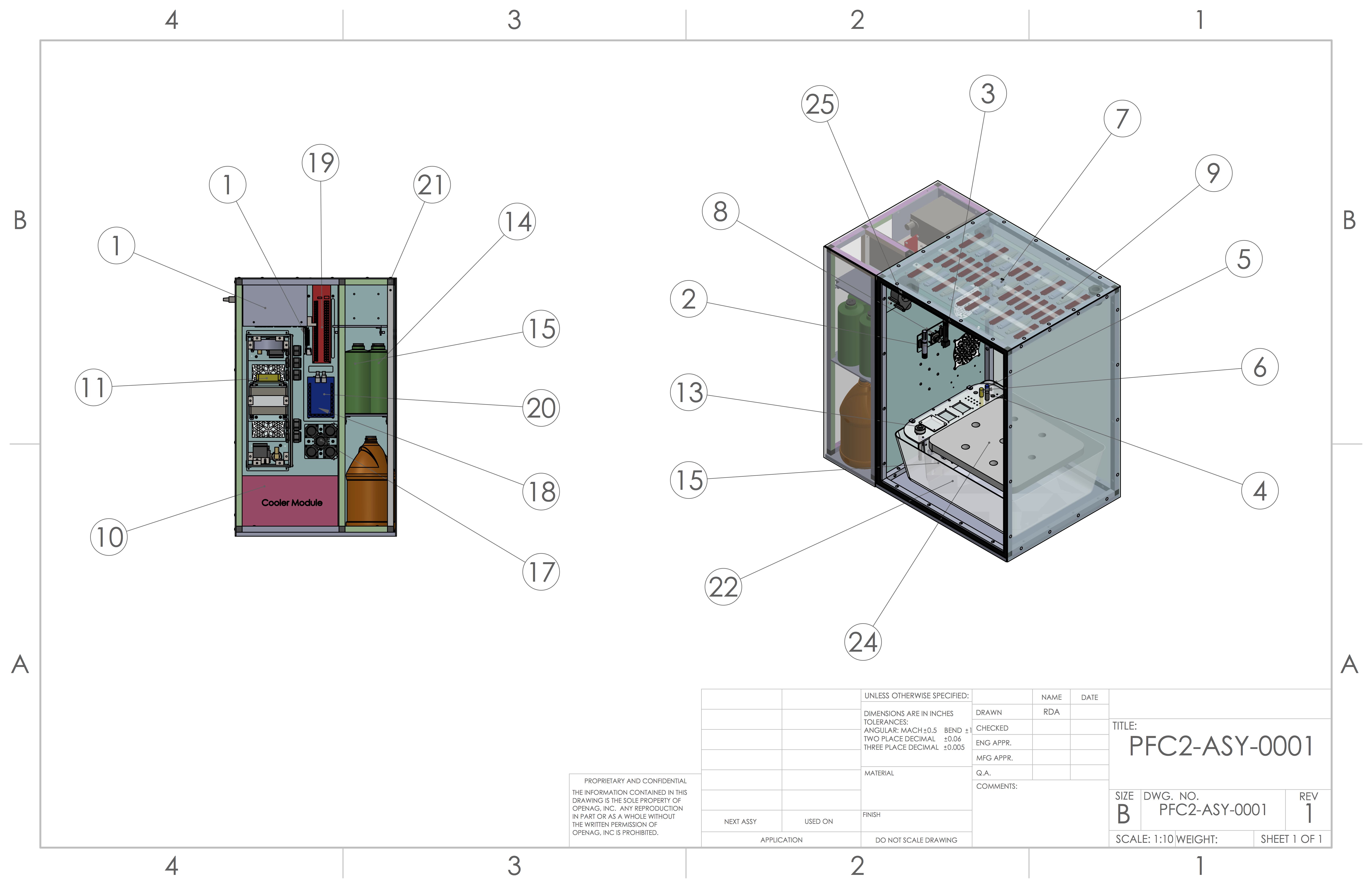

In 2016 I helped develop the Personal Food Computer v2.0 at MIT Media Lab. We love this tool, as do the hundreds of members in our community who have built it around the world. But we learned a lot from this initial deployment. Specifically, it has a long and somewhat expensive bill of materials, particularly for our younger community members. We redesigned its electronics system into a 12”x12” custom PCB, which both added more control and removed some of the burden's of the original design's complexity.

Meanwhile the form factor was compacted down from a 6 cu-ft to an even easier to carry and handle 1 cu-ft volume. All told, we reduced the PFC’s assembly time from a full day and high level of difficulty to an easy 15 minutes. V3.0 also has our new, open-source intelligent LED system at its center, that can control six channels of color and more precisely mimic environments in doing so. PFC v3.0 has been quite the evolution for the team and the project.

Chassis Design

My team at Media Lab designed the PFC v3.0 chassis based on a series of initial constraints:

● Its dimensions were inspired by a trip to NASA, where researchers there use a “3U” cubic-foot outer dimension spec for their space-ag experiments on the ISS.

● We wanted the unit to come together without tooling, so our youngest community members could assemble it.

● All materials must be food safe.

● All materials should be commercially available and affordable.

● A disassembled unit should be able to be flat packed for easy transport.

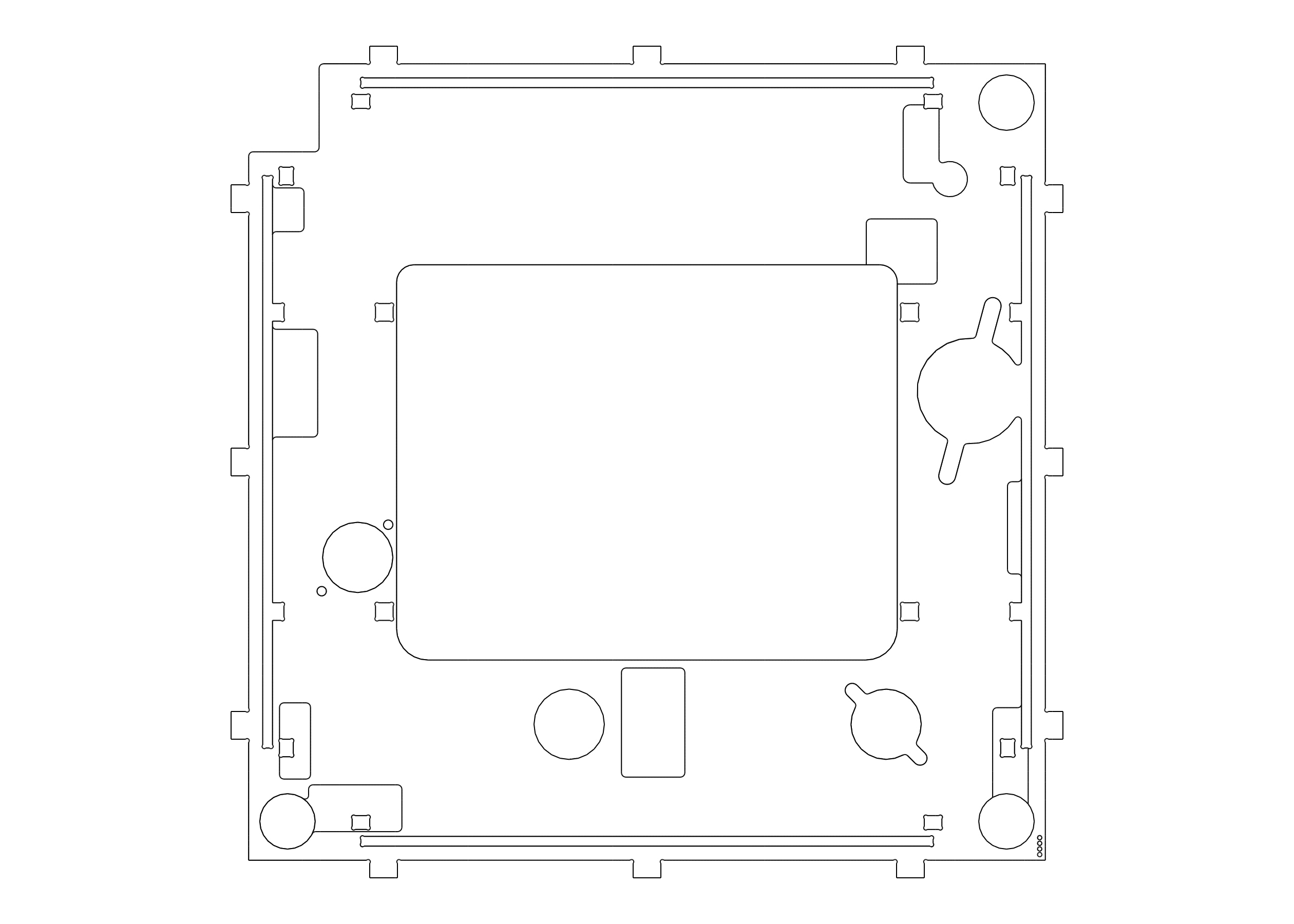

● The chassis needed to accommodate hydroponic plant production, and sensors for electrical conductivity (EC), pH, dissolved oxygen, air temperature, CO2, and humidity for environmental monitoring.

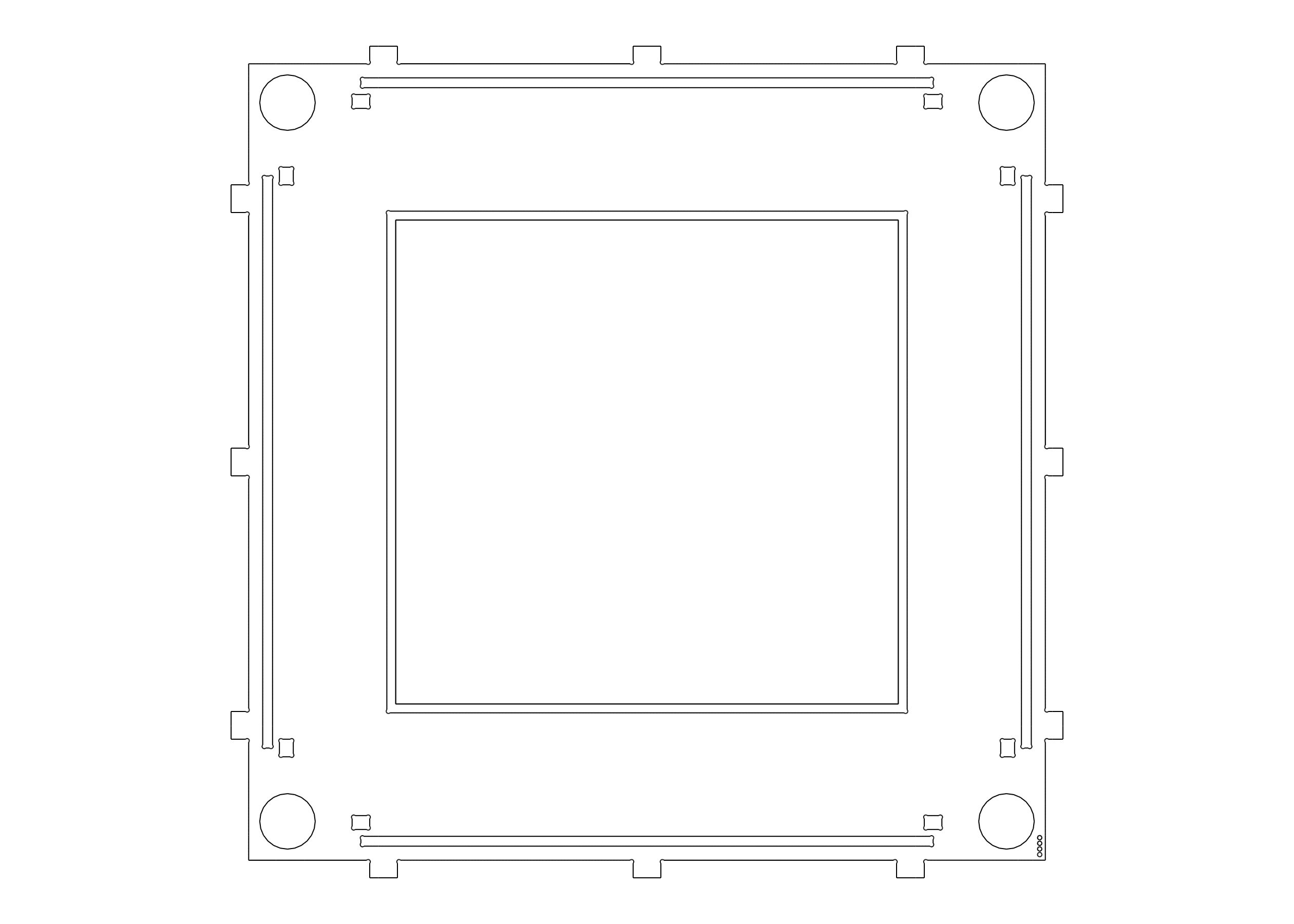

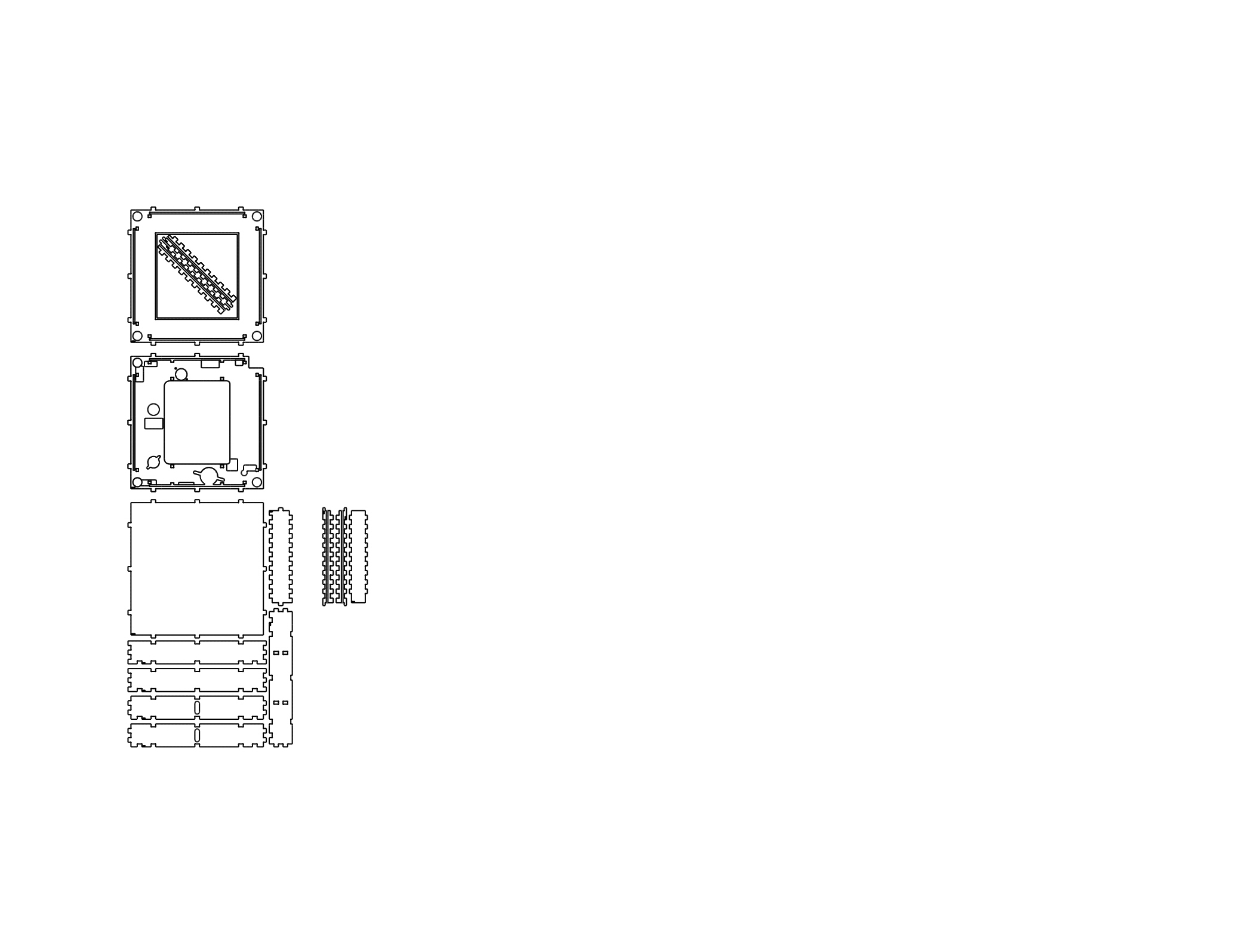

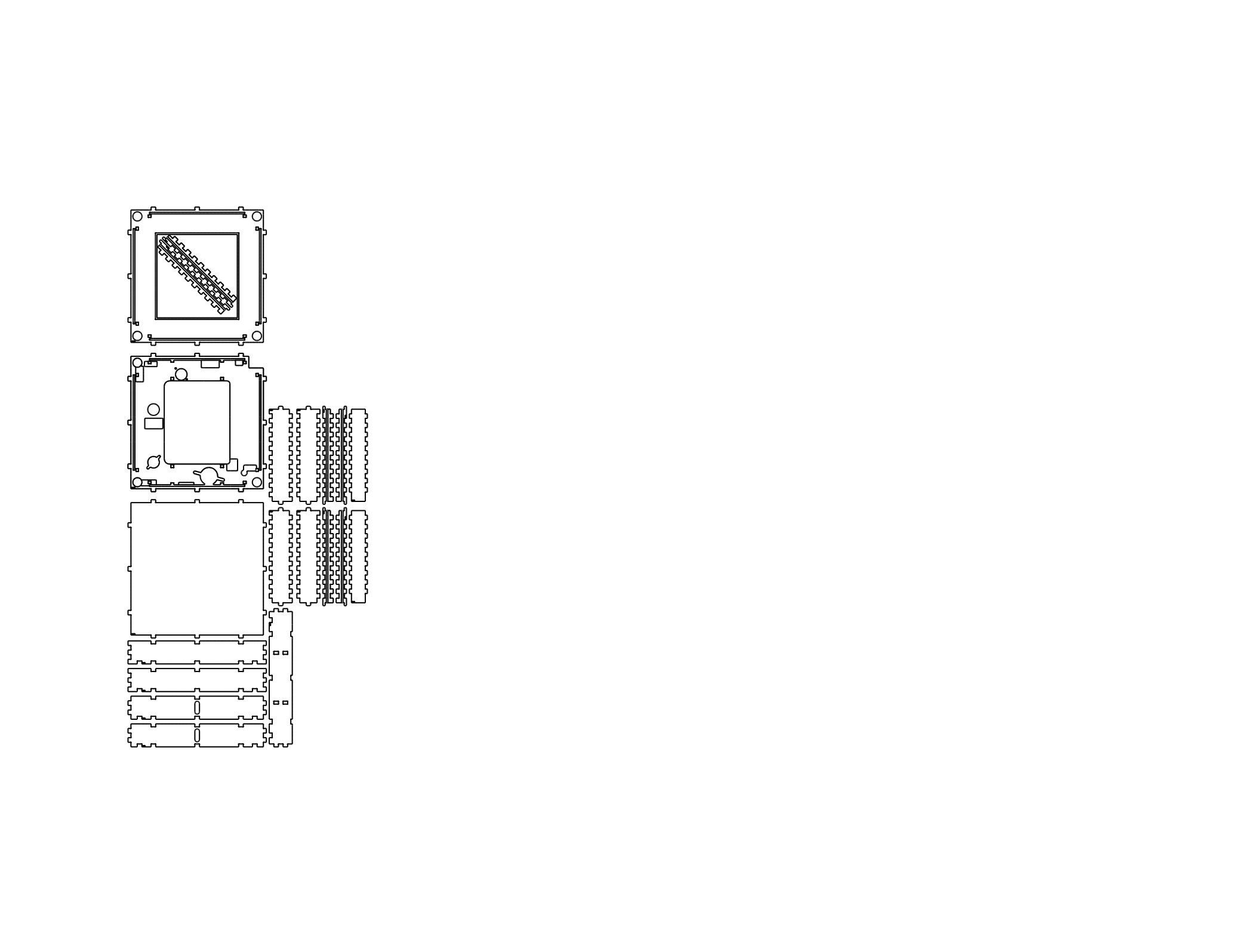

The resulting chassis has press-to-fit jointery, ports for all sensors, and is made of a waterproof, food-safe plastic for ideal hydroponic production. The design was a full team effort, with contributions from our super group of plant scientists, architects, educators, mechatronics engineers, and machine learning experts.

Design for Manufacturing

I added a set of features to the PFC v3.0 CAD model in order to create design and manufacturing efficiencies during the bot’s development, and ultimately to help our downstream users build their own:

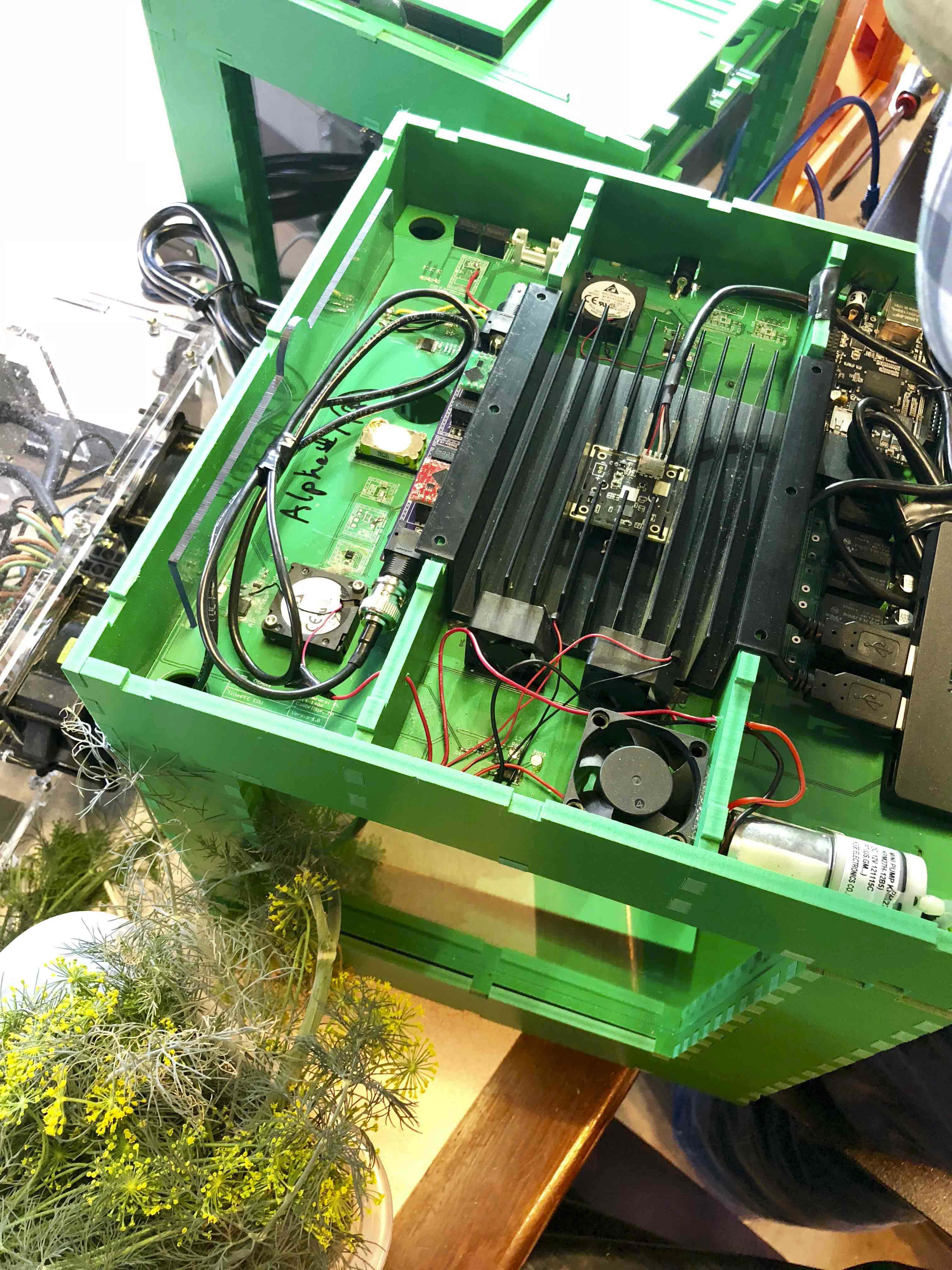

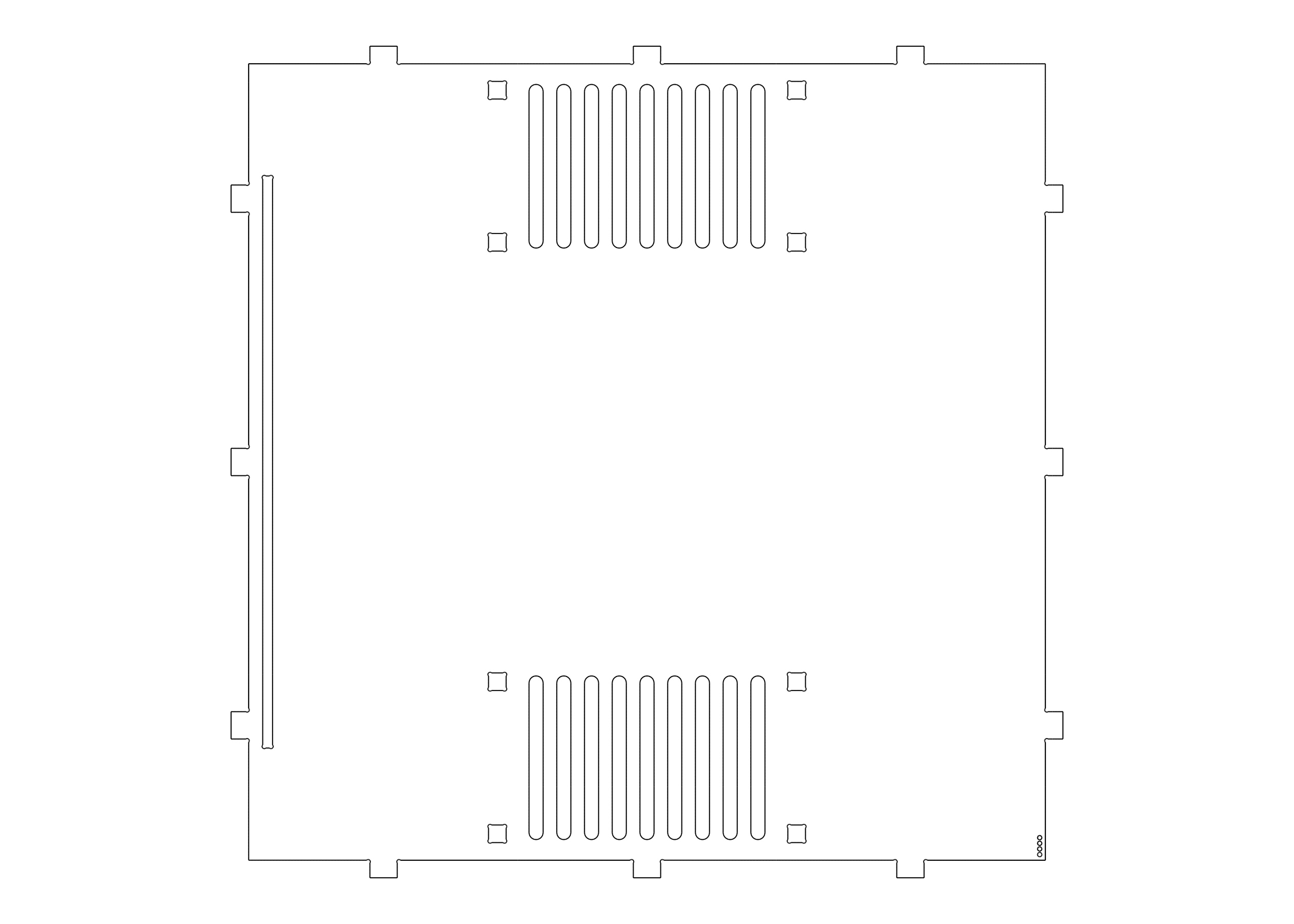

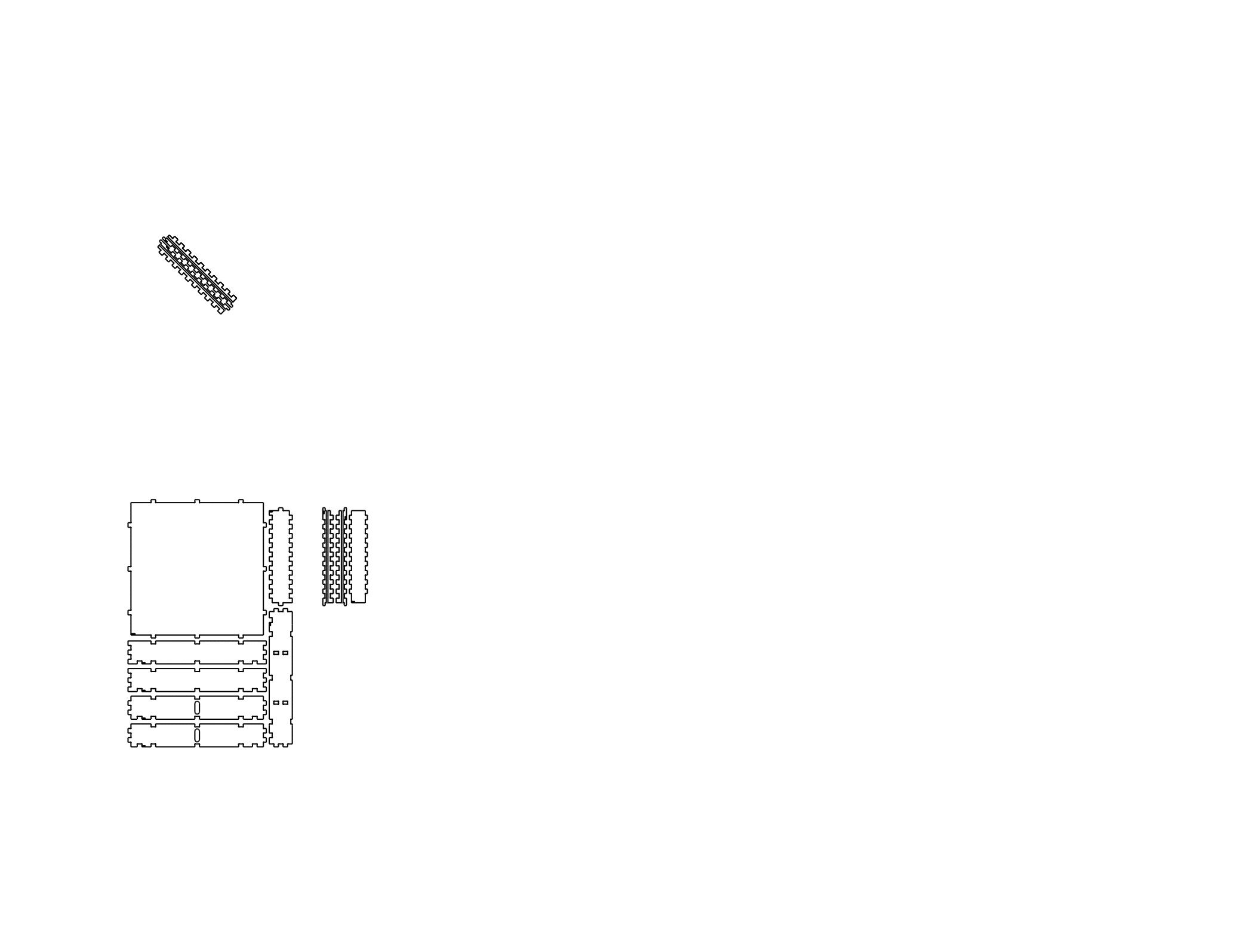

● Flattened part files — I made the chassis’s 41 parts into just eight unique files. This parametric design ensures proper fitting between files and minimizes errors in downstream production.

● Scalability — Growing taller plants? I made the PFC scalable along its z-axis. The change is done by adjusting one height value in the assembly. X and y axes are in the works. Material thickness, too.

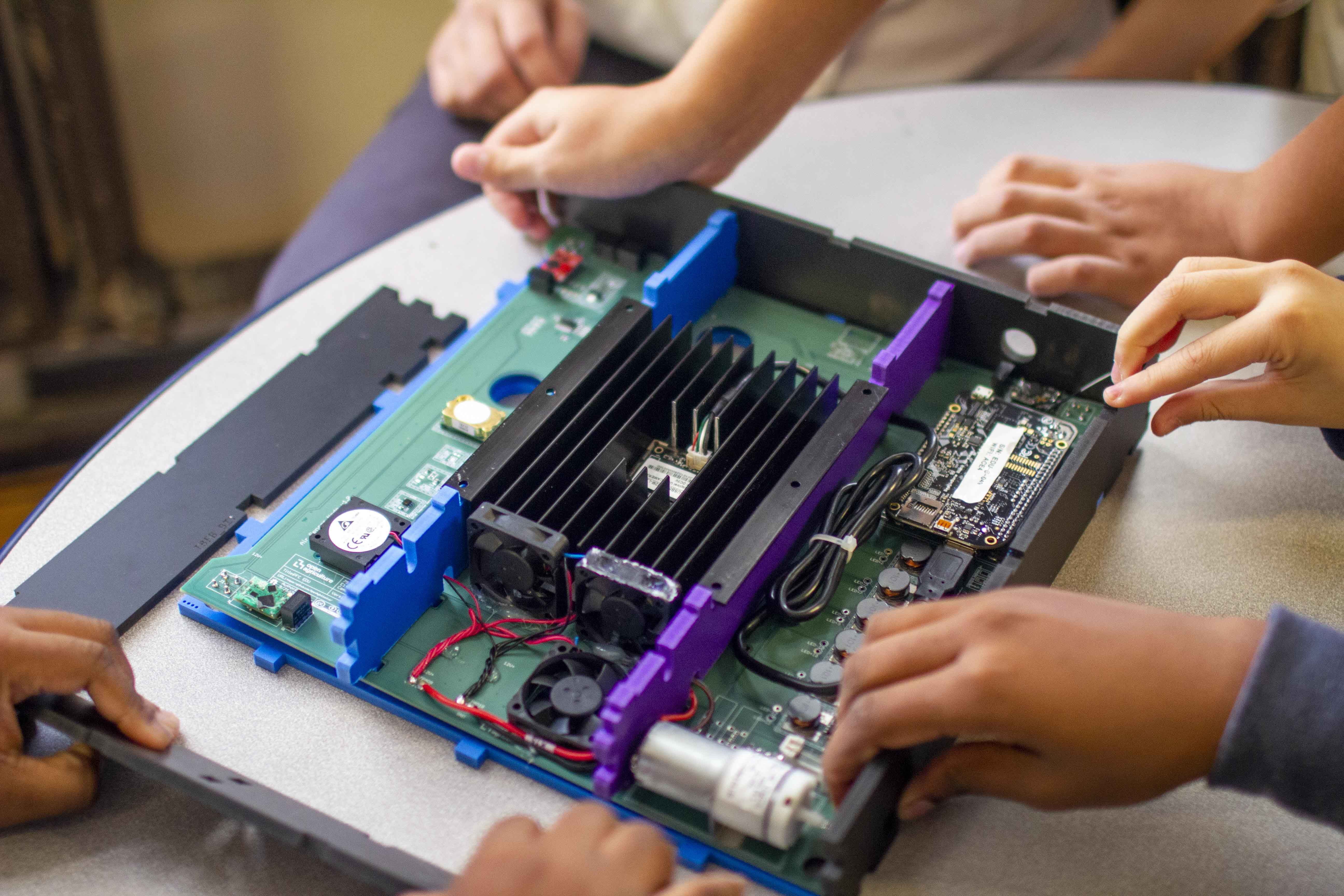

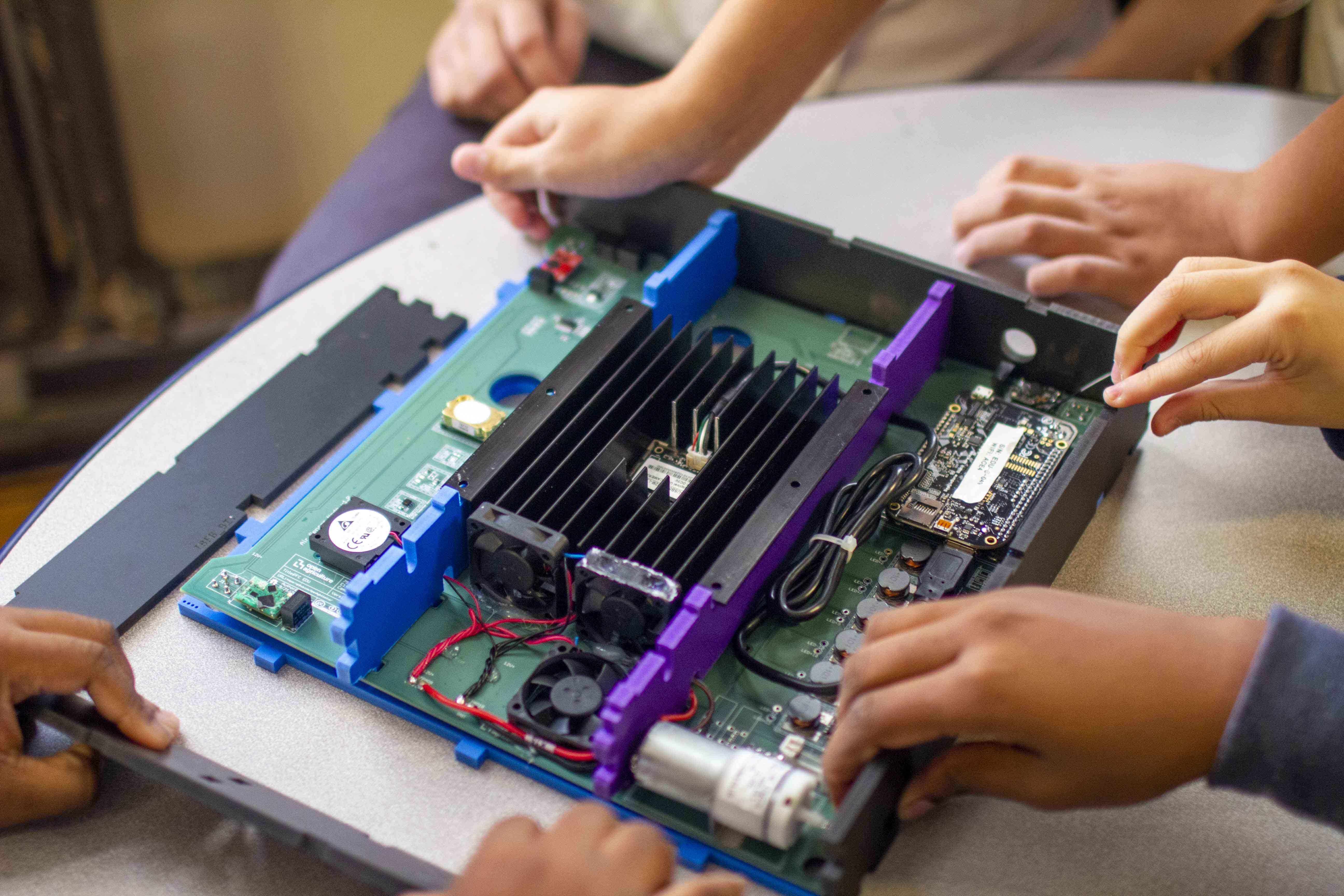

● PCB fit — I worked with my mechatroncis team to fit our custom PCB, the PFC "brain," into just a few centimeters of headroom.

● All machines — I modeled the chassis so that our users can make it on either a laser cutter, water jet, or milling machine. Dog bone jointery accommodates CNC milling inside cuts while also keeping tight tolerances for the PFC v3.0’s air seal. Users can easily toggle them on and off in the 3D model.

● Open-source options — Users have a number of file type options to choose from, depending on their means of production. I populated our Github with STL, DXF, PDF, and Solidworks files.

Chassis Production

I led my team's in-house manfuacturing of the PFC v3.0 during prototype and production phases, using the MIT Media Lab tooling to produce 60 assembled units. Locking step with my electromechanical team, I ensured proper PCB fit, sensor fit, and ease of assembly throughout my iterations. I ended the production run before our deadline, with extra units to spare.

The Media Lab's Shopbot is an old horse, so I came up with efficiencies to speed up production. My pace went from an initial single unit in two days, to manufacturing 15 units per week. Here are some tricks and techniques I learned along the way.

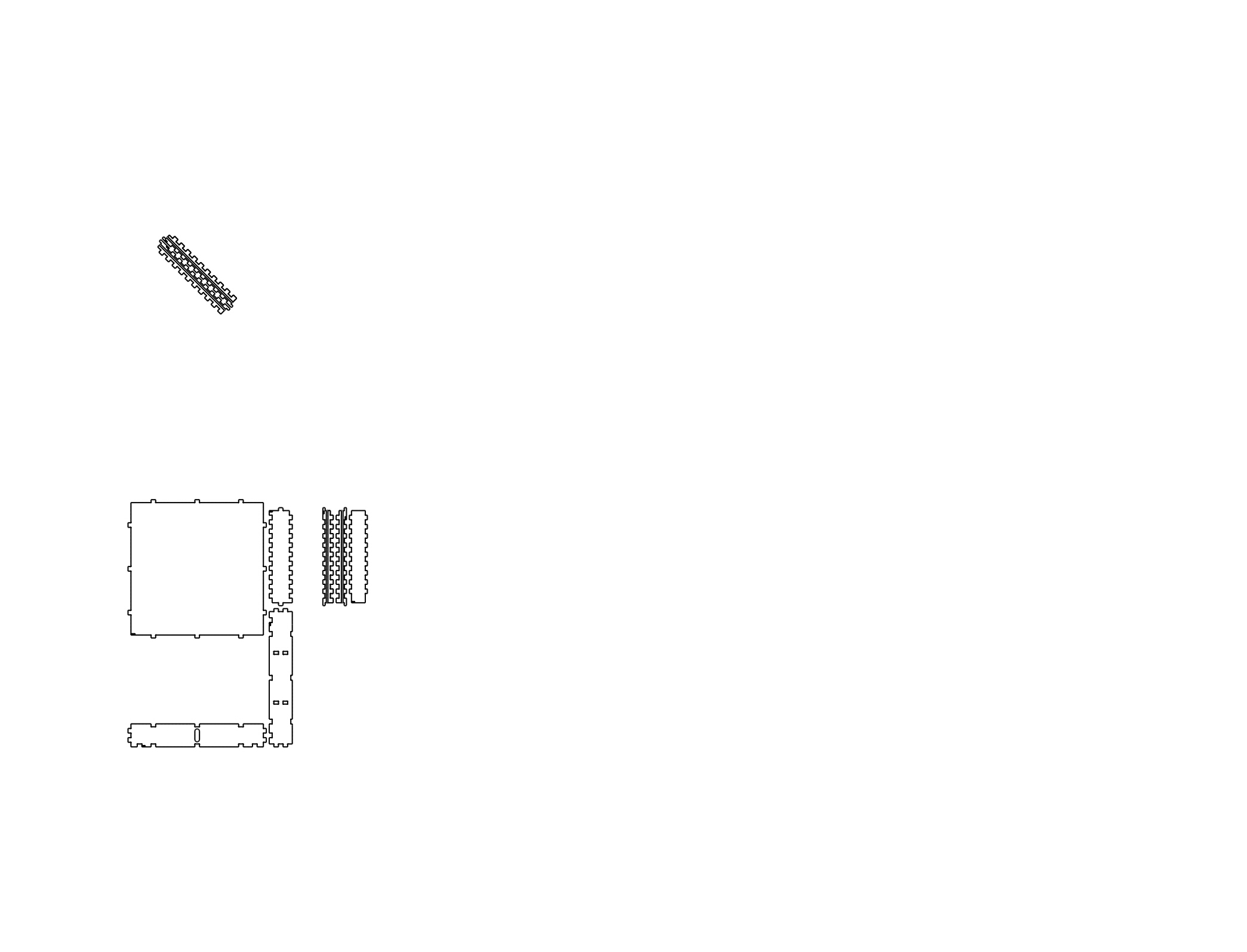

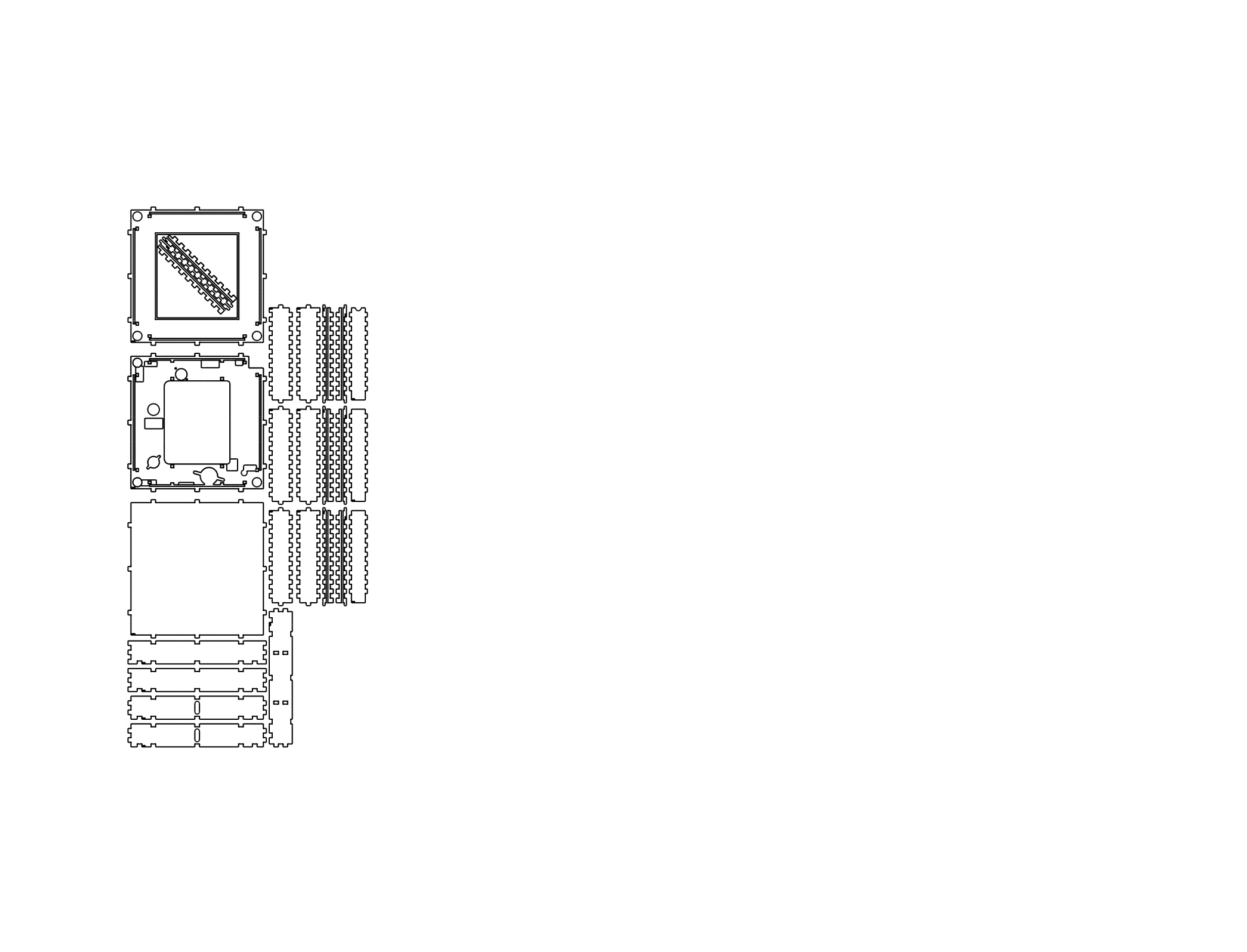

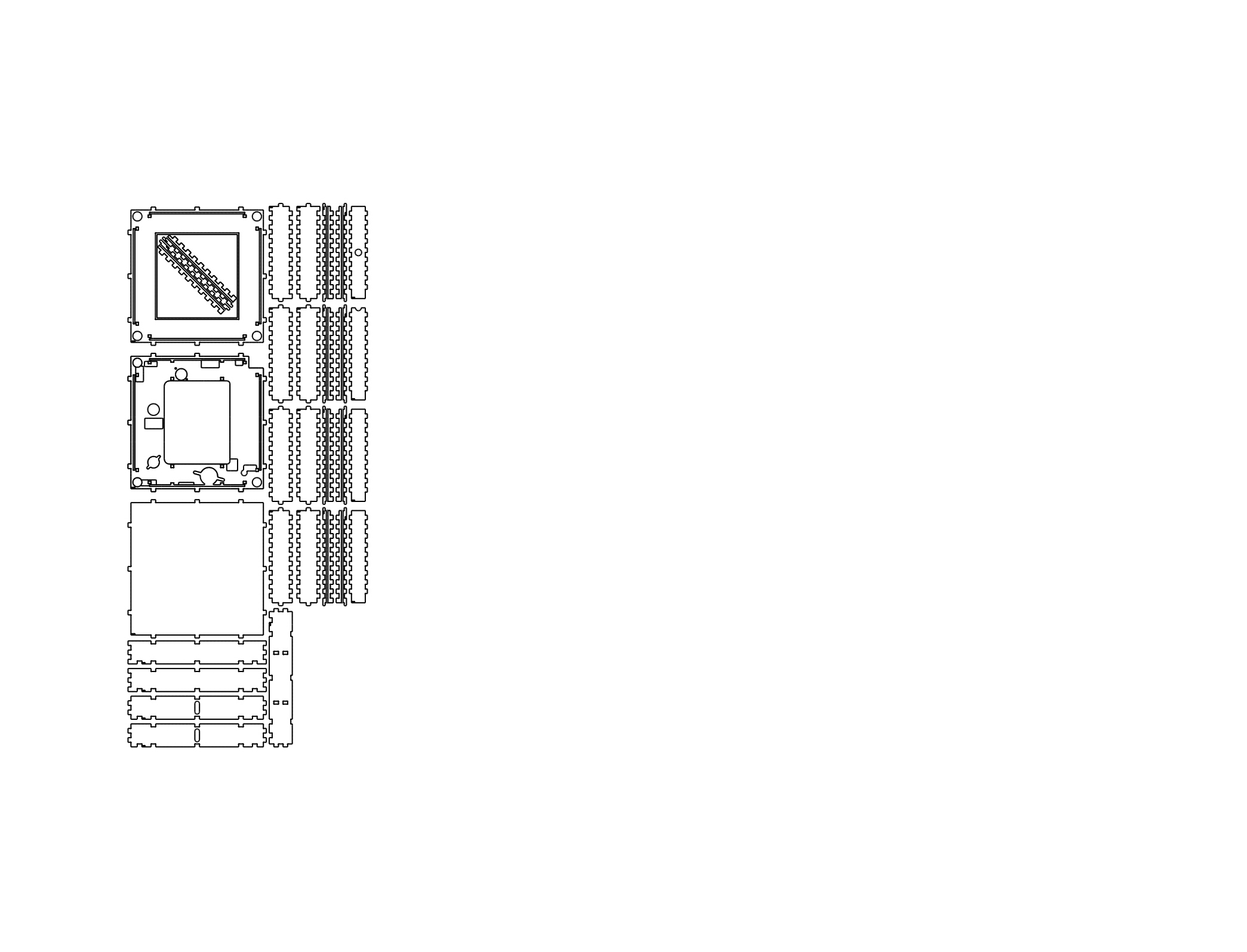

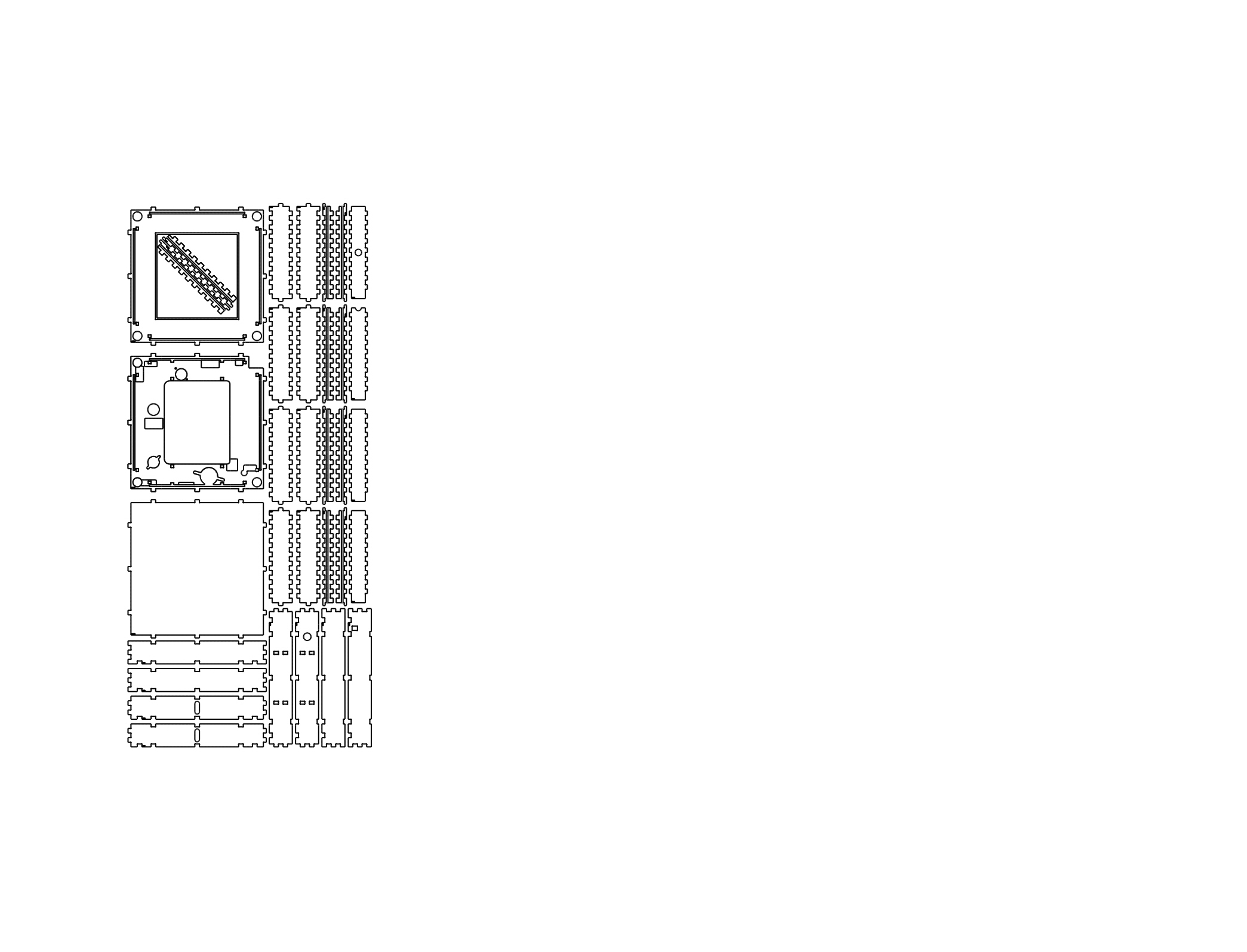

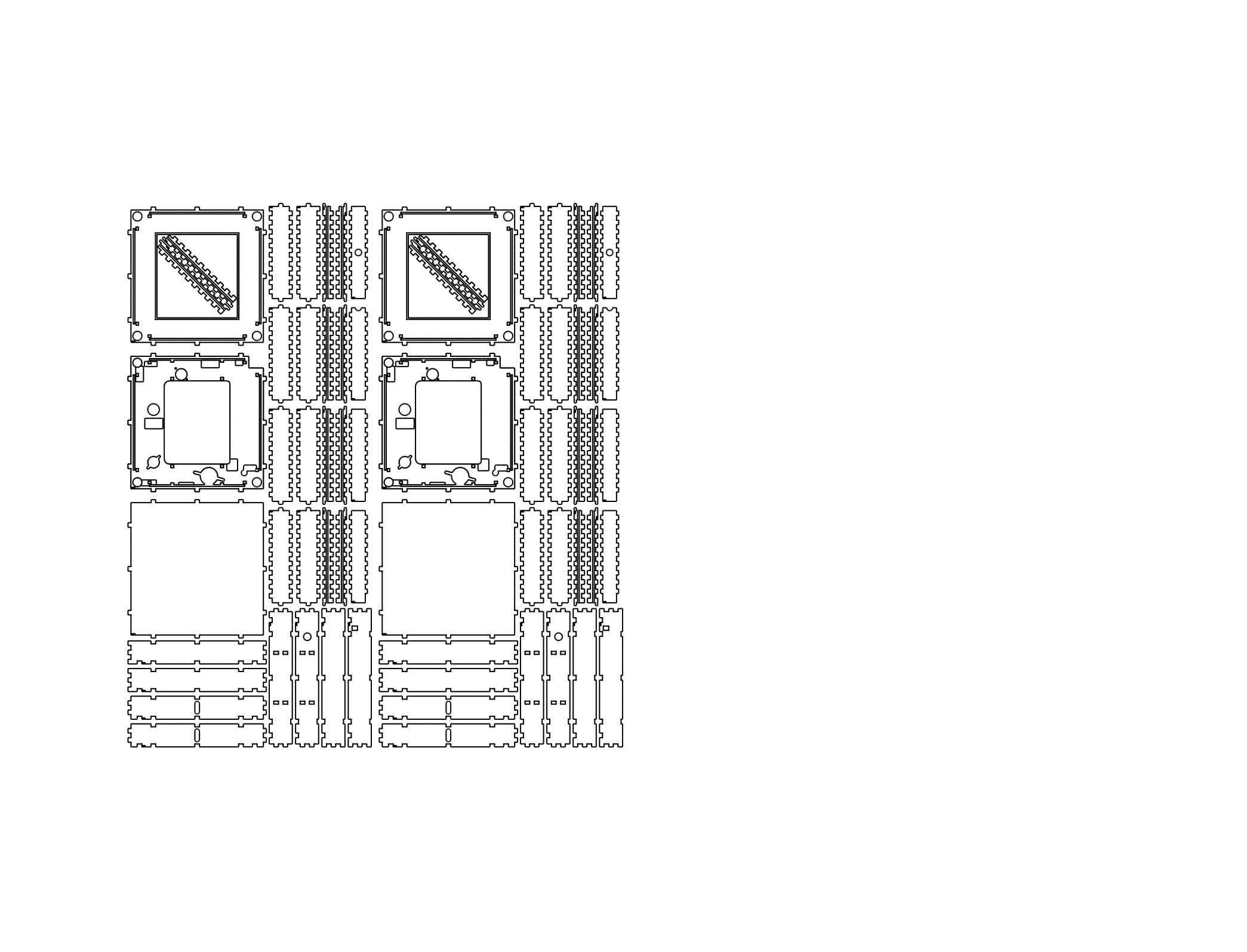

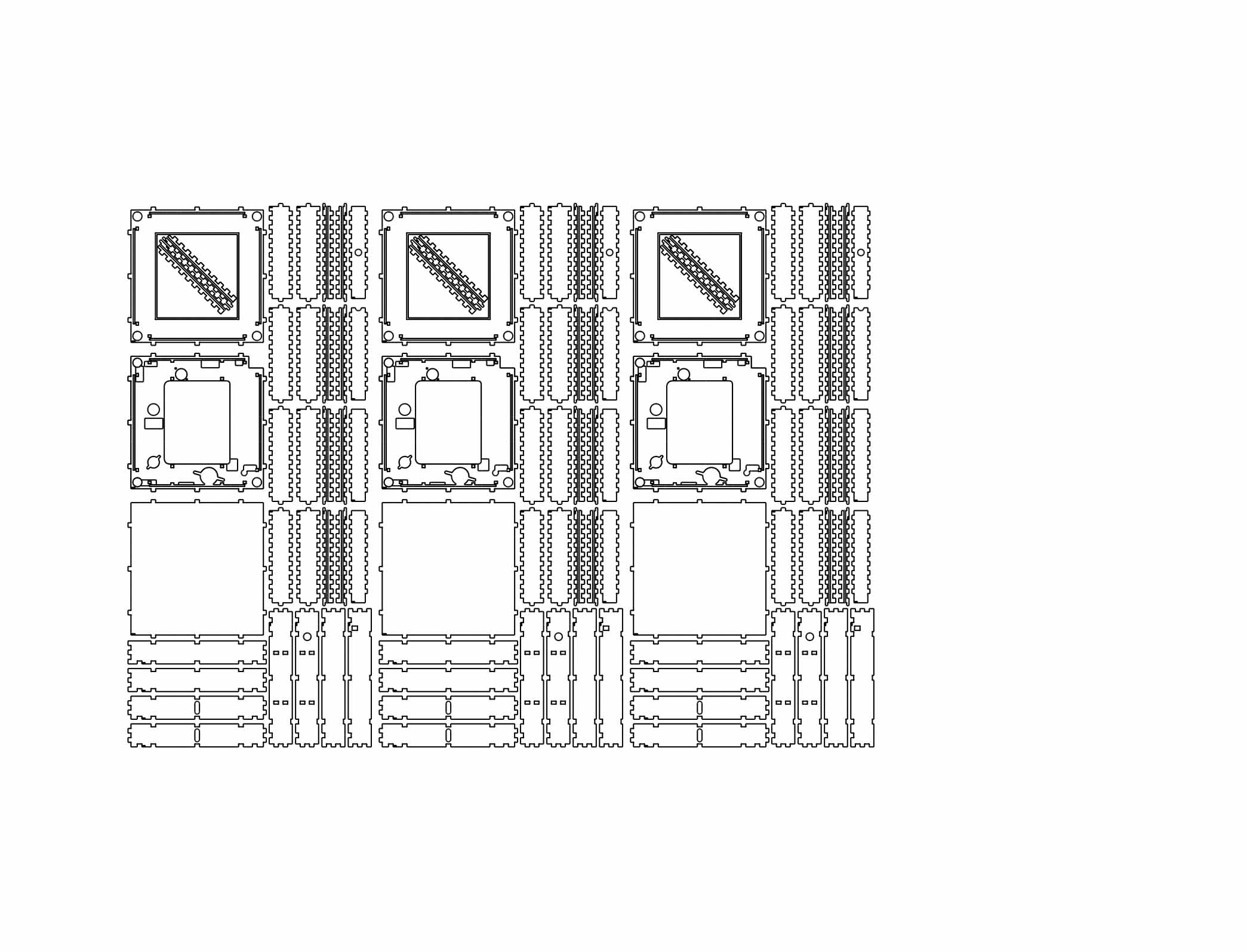

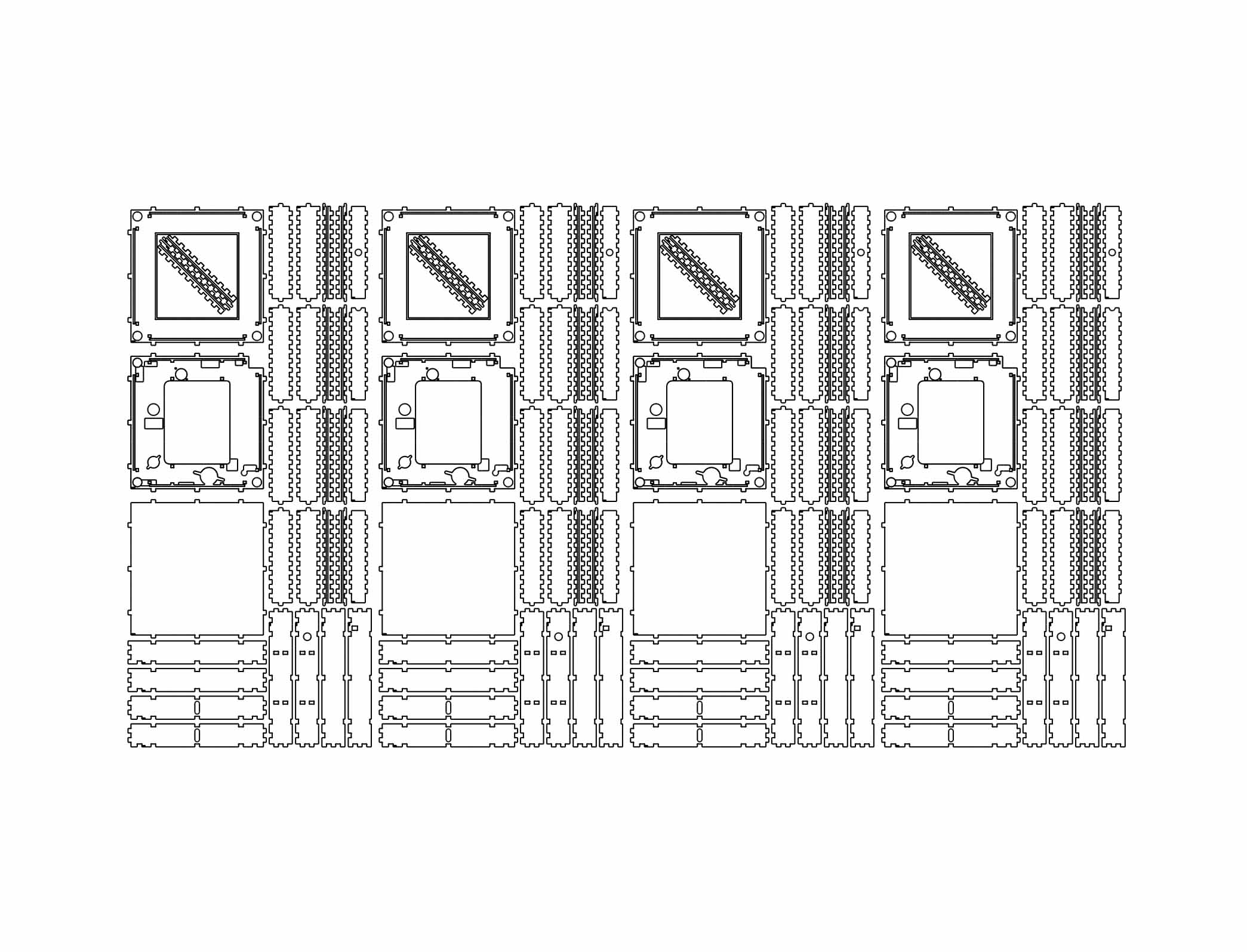

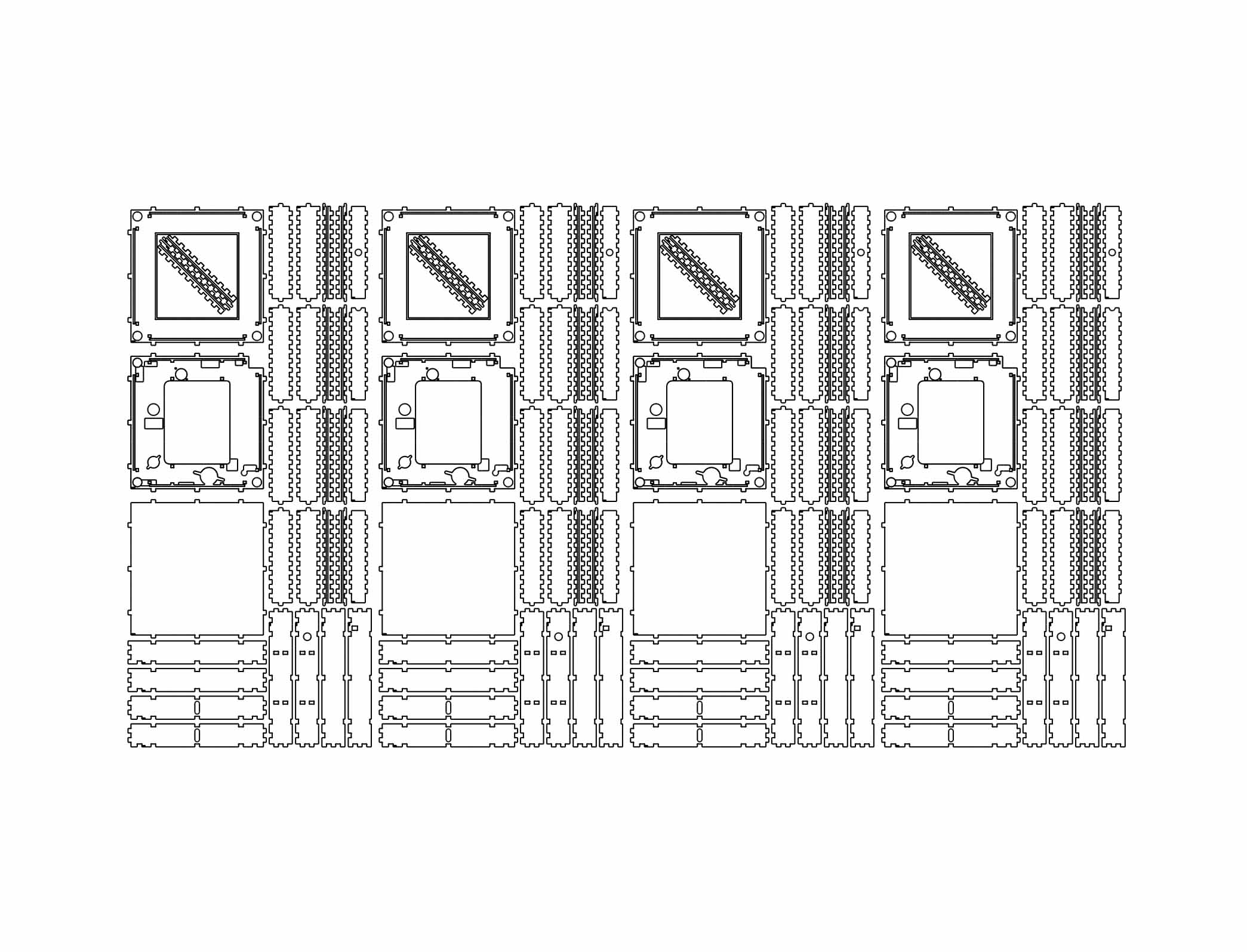

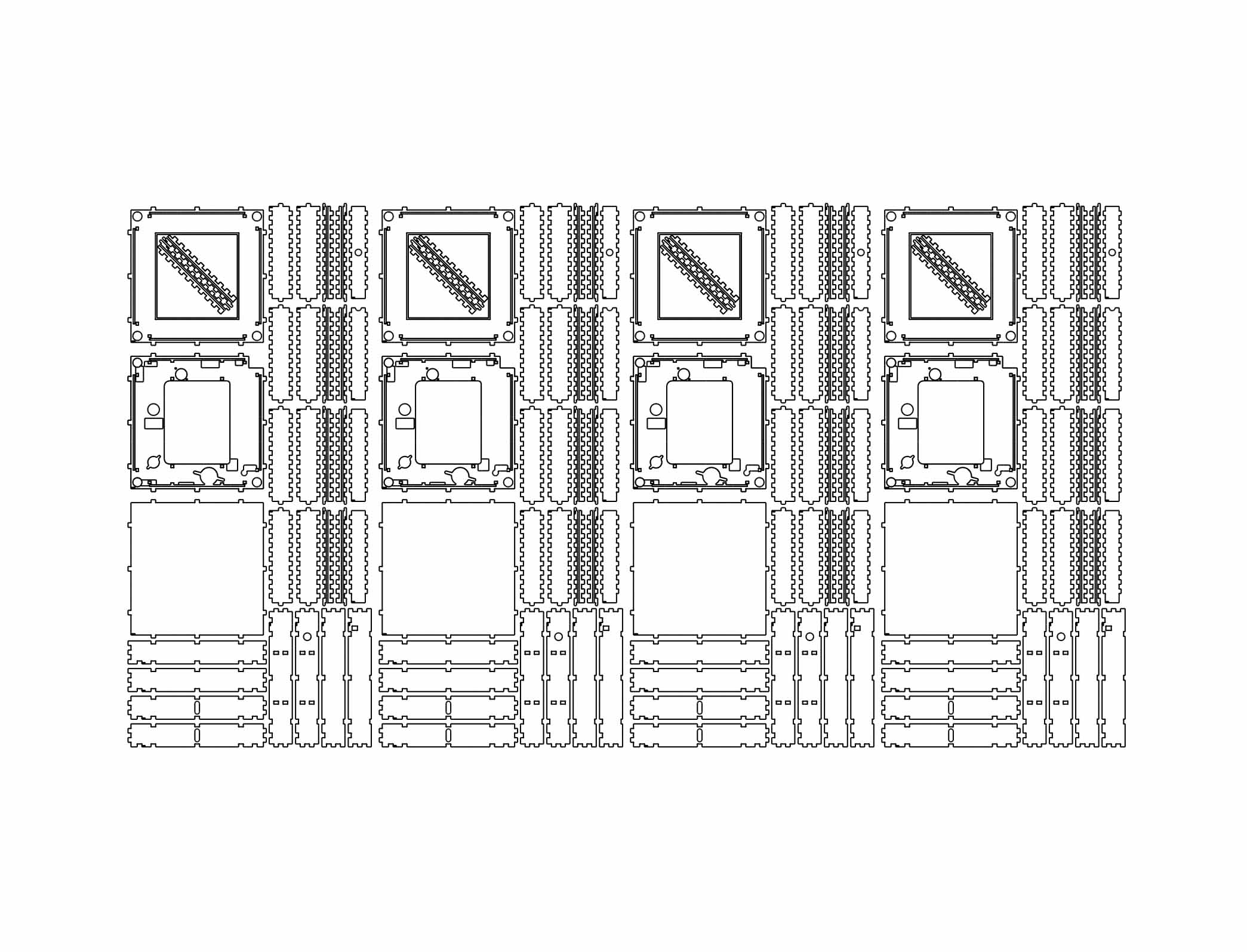

● Solidworks drawing templates — All of my cut files came right off of a custom Solidworks template, pictured above. I saved time not having to set up cut new cut files with each change in my 3D model. They all just showed up in the synced template.

● Material management — Also pictured above, I added parametric functions to my tool paths to maximize cut space and minimize waste. The features reduced cut time and material costs.

● Fine jointery — I tested and found the best cutting tools for production. I based my CAD model off of the fine kerf of 1/16” diameter mill, for the PFC v3.0 inside corners.

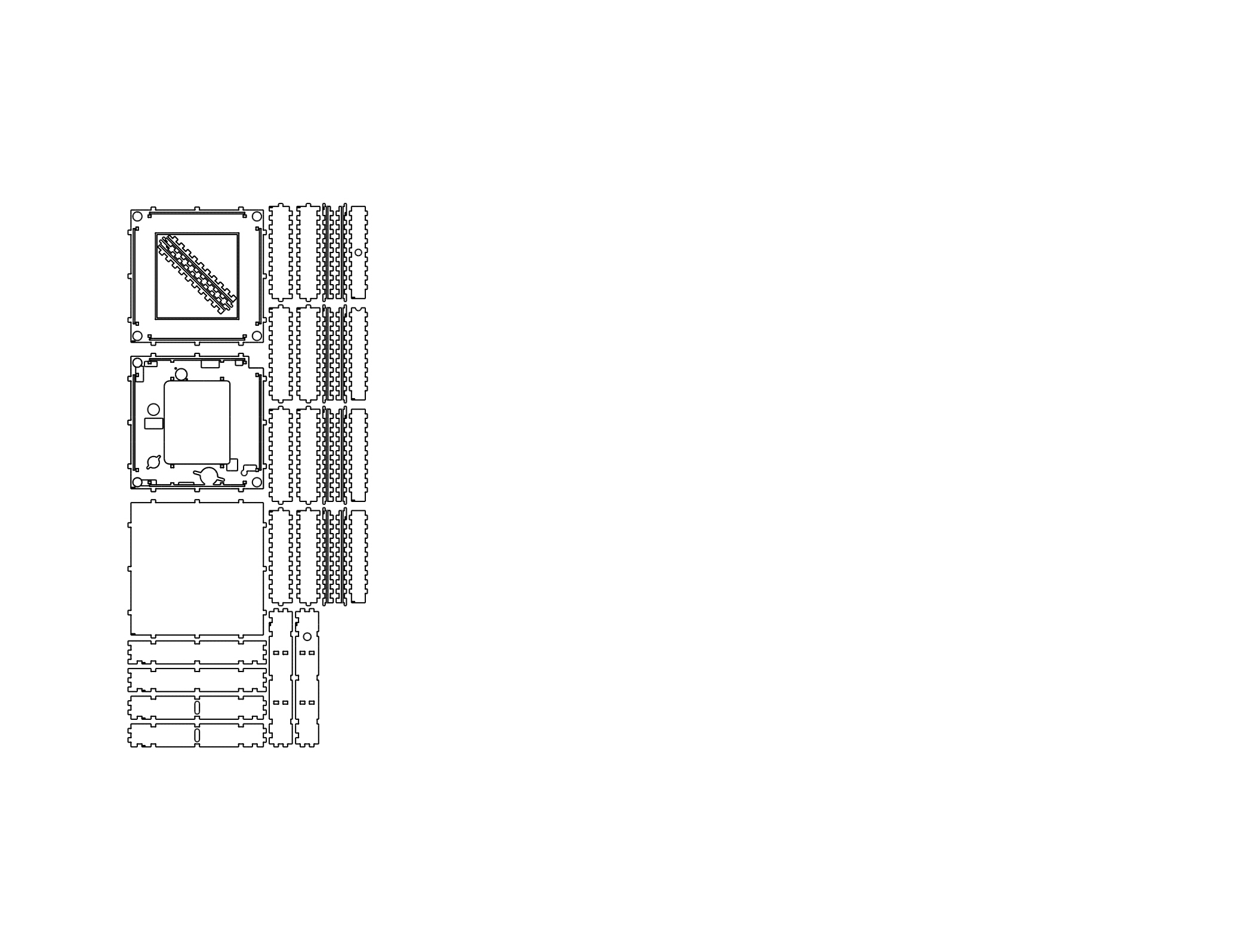

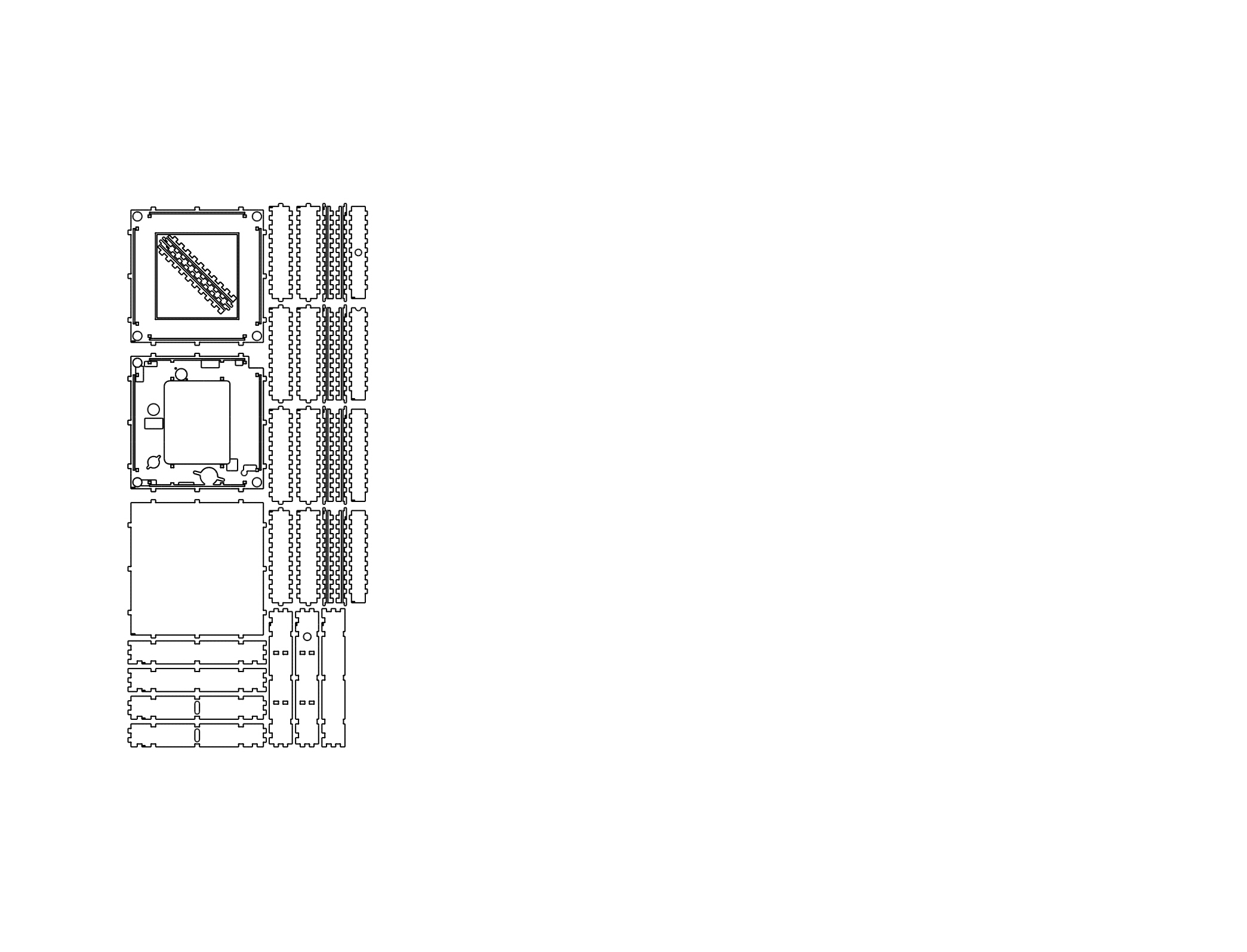

● Engraved parts — Pictured below, I engraved version and part names into all of my chassis components. The step made it easy to track physical changes in the chassis as it was being developed.

Deployment

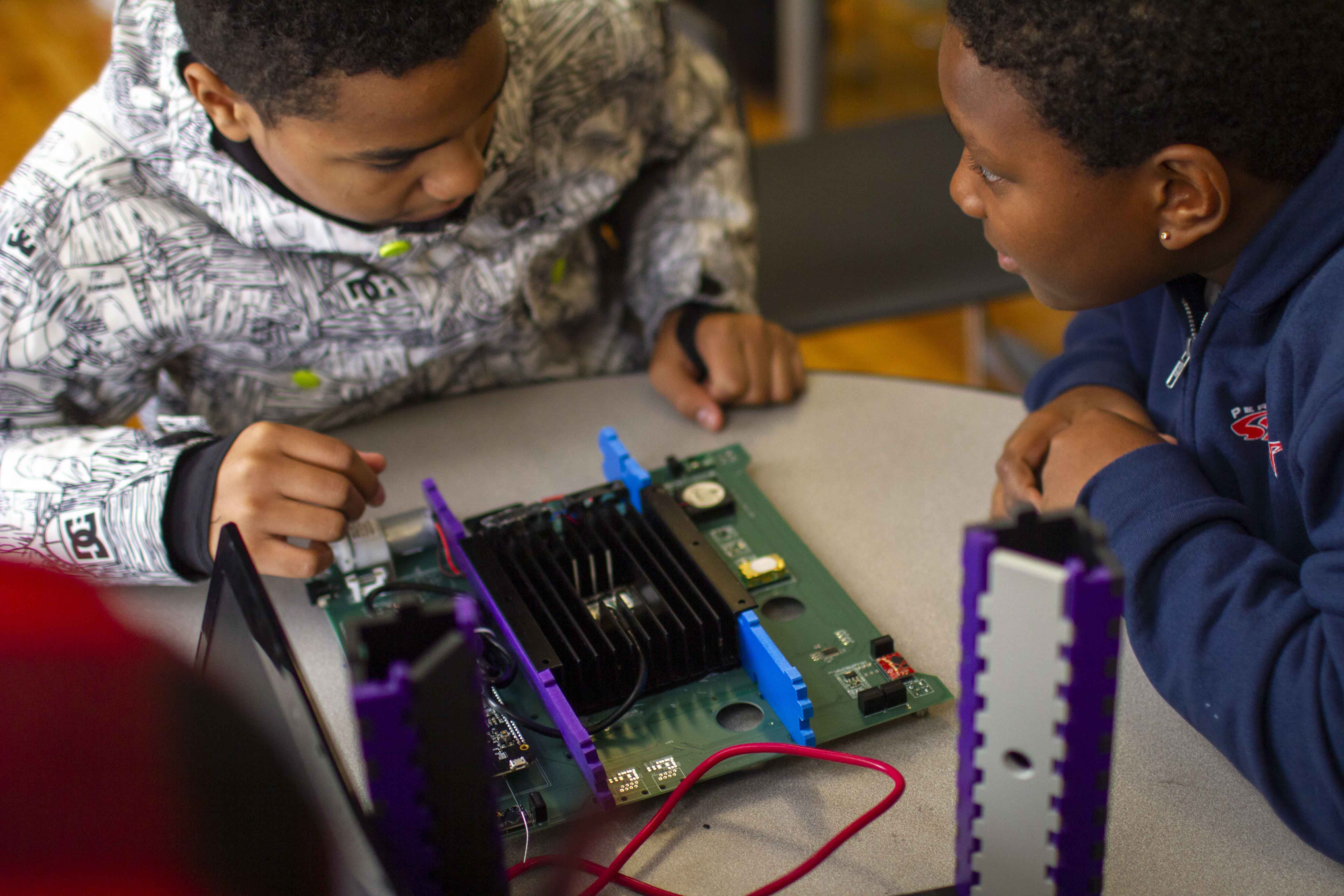

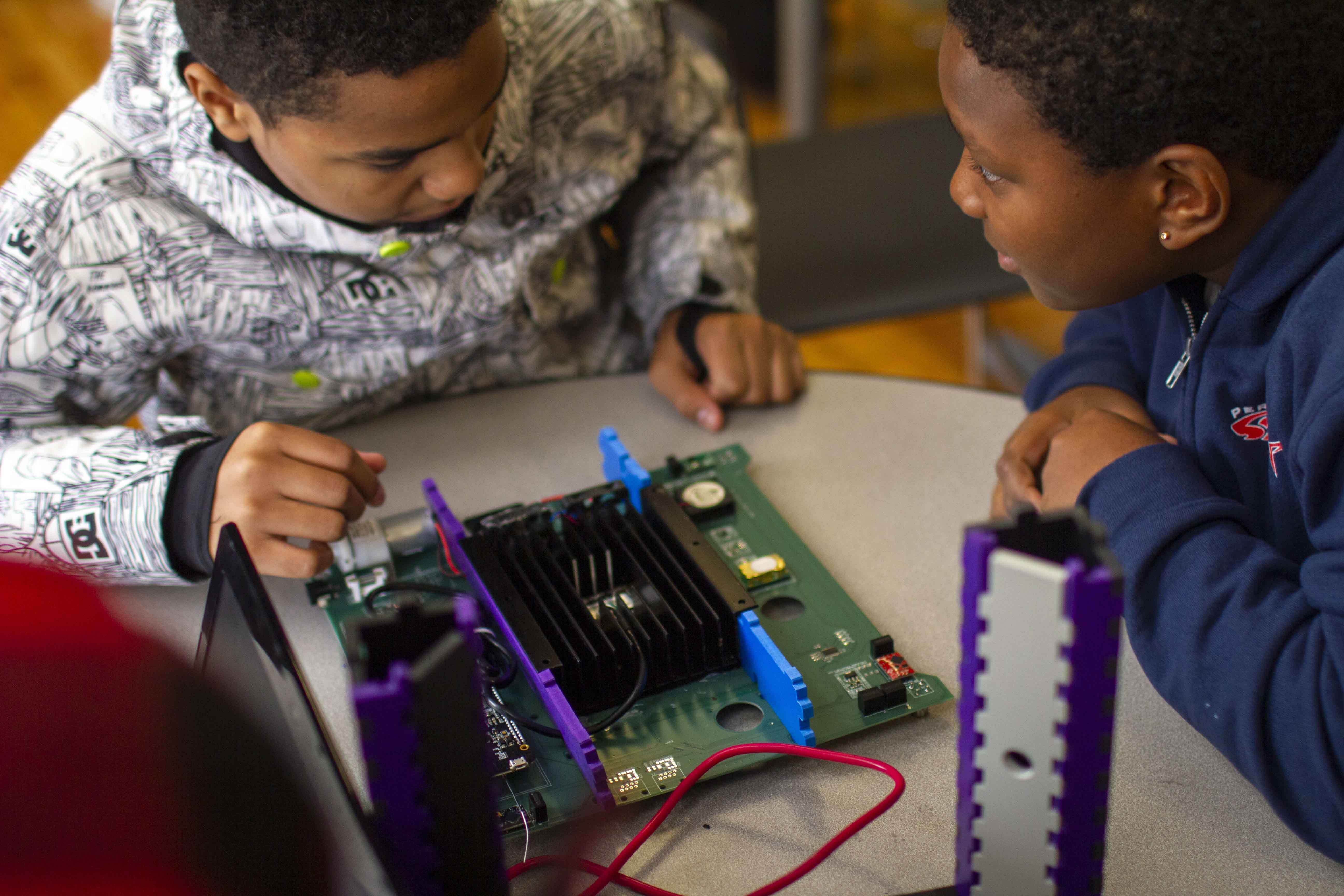

"Deploy or die," as we say at Media Lab. My manufactured units weren't just for demo. They were to be delivered to K-12 classrooms in and around Boston for our user pilot study, led by the human behavior and health specialist side of our team. Meanwhile my mechanical files were shared on our Github and Wiki to our thousands-strong community.

To me, the user study embodies the Media Lab's and my own devleoping approach to tool building and research. In building a hardware tool, the PFC, to forward knowledge in plant science, we in turn are making a tool to advance human expression and interaction. The PFC v3.0 is not only a controlled environment growth chamber for advancing plant science, but also a platform through which its users can learn, interact, and express.

I'm looking forward to seeing how our open-source community will deploy their own PFC v3.0's. Perhaps they'll design the "sweetest" tomato, and share it on our forum for others to grow and taste. Or they might explore climate change science, like the kind I worked on in my previous lab, incubating their own local woody plant species to see how they'll respond to future a warming climate. Better yet, they'll build and hack their own PFC 3.0 mod, for new uses our team has yet to think up.